1165 N. Stanford Avenue

Los Angeles, CA. 90059Mon - Fri 8am - 4pm

Closed Sat - Sun310.532.7870 | 310.532.1014

ZUMBACH WALLMASTER

UMAC® Eccentricity and Wall Thickness Measurement with Ultrasonics

UMAC® represents a complete line of non-contact ultrasonics based systems for wall thickness measurement and  control of pipe, hose, tubing and cables.

control of pipe, hose, tubing and cables.

The heart of each system consists of a highly developed UMAC® measuring system, interrogating up to 16 sensors at high speed. WALLMASTER systems process data from several ODAC® measuring heads and a UMAC® Wall Thickness and Eccentricity System located immediately after the extruder. Automatic closed-loop control of wall thickness and/or diameter is easily possible.

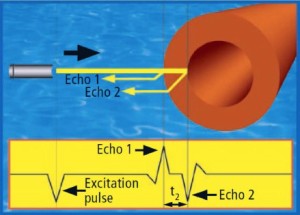

Ultrasonic Measurement Principle

It is based on the time difference (t2) of the sound echoes from the surface and the inner side of the product. A piezoelectric crystal is excited by a sort electrical pulse. The crystal converts electrical energy into mechanical energy, i.e. sound waves. When the sound waves encounter a difference in the propagation medium (for instance when passing from water to a synthetic material), a part of them is reflected back to the crystal (echo). Wall thickness = Sound velocity of material x t2 x 0.5

It is based on the time difference (t2) of the sound echoes from the surface and the inner side of the product. A piezoelectric crystal is excited by a sort electrical pulse. The crystal converts electrical energy into mechanical energy, i.e. sound waves. When the sound waves encounter a difference in the propagation medium (for instance when passing from water to a synthetic material), a part of them is reflected back to the crystal (echo). Wall thickness = Sound velocity of material x t2 x 0.5

An Echo Says What?

Any company that insulates electrical conductors with thin walls of different insulating polymers knows how challenging it can be to achieve and maintain an accurate conductor center throughout your entire production run. With wall thicknesses down in the .003 to .006 of an inch range, even the engineered clearances in the extrusion tooling can make mechanical corrections difficult to navigate. Understanding that tighter mechanical tolerances will equate to tighter electrical performance, how can you inspect and monitor your production runs, in a real time and in a nondestructive manner?

With an Echo of Course!

At Systems Wire and Cable, with our goal of being relevant and on the forefront of the Custom Cable Industry, we have made significant investments in several ultrasonic Wall Master Systems manufactured by Zumbach Electronic AG. This technology as described above, allows Systems Wire and Cable to monitor and control corrections in Wall Thickness, Outside Diameter, and Conductor Eccentricity, with display resolutions accurate to .0001 of an inch.

At Systems Wire and Cable, with our goal of being relevant and on the forefront of the Custom Cable Industry, we have made significant investments in several ultrasonic Wall Master Systems manufactured by Zumbach Electronic AG. This technology as described above, allows Systems Wire and Cable to monitor and control corrections in Wall Thickness, Outside Diameter, and Conductor Eccentricity, with display resolutions accurate to .0001 of an inch.

- UMAC Wallmaster

- Ultrasonic Wall Measurement

These higher accuracy’s translate to tighter electrical performance as well as material savings resulting in a win win for our customers. Since the implementation of these Wallmaster Systems in 2014, Systems Wire has experienced exponential improvements in our cable products primary conductor and jacketing wall tolerances. These systems were chosen due to their extraordinary reliability and their future expandability with neck down and lump detection, ac spark testing, and statistical data collection functions. At Systems Wire and Cable, we understand the investing in technology is a necessity for a company with a modern business model.

We hope our customers who source their custom wire and cable requirements from Systems Wire and Cable trust and appreciate our commitment to excellence.

.png)