1165 N. Stanford Avenue

Los Angeles, CA. 90059Mon - Fri 8am - 4pm

Closed Sat - Sun310.532.7870 | 310.532.1014

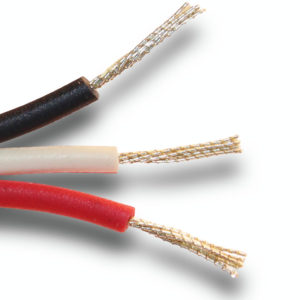

BONDED TINSEL WIRE

Thermal Bonding – Glueless Bonding

Thermal Bonding of Kevlar Aramid Tinsel Conductor is an area that Systems Wire and Cable has developed for many of its Custom Medical Manufactures. When Conductor Tinsel Strength and Flexibility are a must, this Conductor Material is hard to beat.

Thermal Bonding is a process of using Hot Air to join multiple Conductors of the same polymer to one another. While Thermal Bonding can be done with a wide variety of polymers, it does have some limitations in regards to Crosslinked and Flame Retardant materials.

Thermal Bonding is a process of using Hot Air to join multiple Conductors of the same polymer to one another. While Thermal Bonding can be done with a wide variety of polymers, it does have some limitations in regards to Crosslinked and Flame Retardant materials.

With that being said, Systems Wires and Cables Thermal Bonding process has evolved to be the go-to source of adhering Tinsel Conductors to one another without the Contamination, Mess, and Added Expense when comparing it to the Flood Adhesive Bonding process. No Glue means No Voids, Gas Bubbles, or Material Stripping Witnesses from when the Material is separated to terminate.

Systems Wire and Cable is always willing to provide Samples on new projects for Qualification and Compatibility Testing as well as Quoting purposes. While the boundaries of this process seem somewhat limitless, we are restricted to quote only constructions with Finished Product Widths Less than 1.0 inch Wide.

When it’s time to make that bunch of loose wires looks aesthetically pleasing, let Systems Wire straighten them out for you.

.png)